|

|

|

| |

|

#1

|

|||

|

|||

|

One of the locals had an itch to shoot F-class at 600 from the bench. Not really a registered class but at the local range they call it Geaser Class (G-Class) as in a bunch of Geasers get together and make their own rules. Basically he had a Light Varmint Tapered barrel at 28", a Tikka T-3 action, and a .243 Reamer and dies. He also had a big Richards micro fit stock... Without trying to step on any toes... From what I've seen, "Micro fit" really means (in the ballpark). So he wanted to mount this Big Barrel on this little action. He also had the worry of only being able to use the supplied Tikka rings. This rifle will be a shooter during the summer months for matches, yet has to transform back to being a .308 Winchester Deer rifle for the fall. I had him leave the rifle with me and told him I would get to it in time.... You all know how that goes.

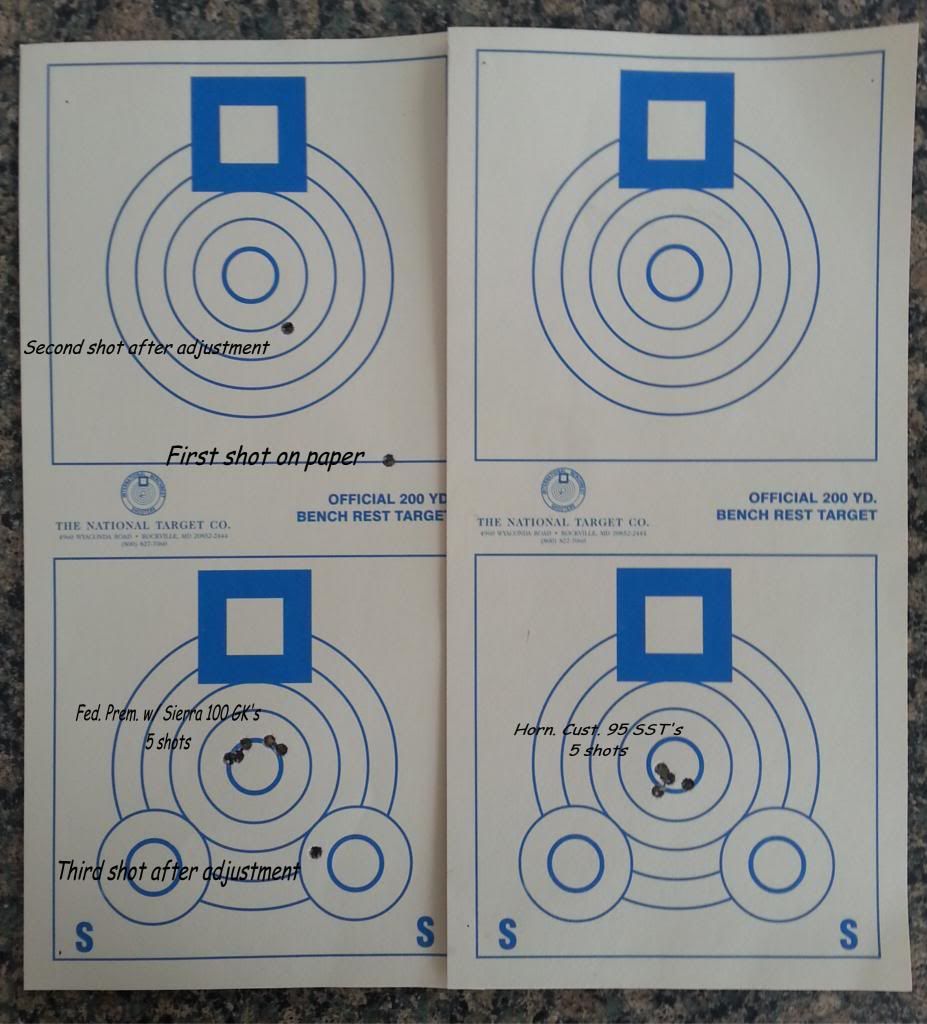

He left me the rifle last July, his only concern was that it be ready this spring so he could compete with it in the G-Class at the club. I had it ready for him in early to mid January. I started on it in December.... I had most of the year to consider just how I would tackle this job. Without showing the pictures, first let me explain, He now has a rifle that has the action completely free floated except where the functioning detachable box magazine rides, He now has a barrel that is in a block for 4 inches, he now has a Picatinny rail with 10 minutes down taper that is solid to the barrel block, and the Barrel block is bedded in the stock for 10 inches (glued and screwed). The entire Bedding block except where the barrel contacts the block (4inches) and where the glue (devcon aluminum)holds, I pained Cerakote black (baked on). I just had to shoot it before I gave it back so I went to another range where they have an indoor shooting shed that you open the windows to shoot 200 yards in the winter. The day I got out there is was 20+ mph wind, the temps were -4 F, and it hurt just to go hang targets at 200 as I trudged through 1 1/2 feet of snow. There and back is 400 yards. We built a fire inside in the Franklin stove and warmed up before we were ready to brave opening the window to shoot. Since it was a .243 Winchester Standard Chamber, and because I don't reload for .243, I bough store ammo for deer hunting. Federal Premium with 100 gr sierra GK's, and a box of Hornady Custom 95 grain SST's. The Hornady shot the best with a clover leaf group at about .750 at 200, while the Federals sucked with about a .900 group in a smiley face at 200. actually for the conditions, and the fact that these rounds aren't tailored to this chamber, the rifle did remarkable. The complete rifle is 14 pounds 8 ounces without the but plate (he was going to install) or the clear coat. With the scope it will be well under 17 pounds. It has a 3 inch forend, and a trigger with a safety, and a detachable box magazing that works. It should fit into F class, or 600 BR rules should he want to compete that way. I think he will just be a local club shooter in G class, too bad, cause the gun is worthy. I am considering selling these "Barrel Bedding Blocks" as a kit, everything will be ready for you to glue it into your stock of choice, a 1.200 barrel shank will be needed , and preferably you have that size for 4 inches. The kit will have the Picatinny rail with 0, 10 or 20 minutes of taper. The whole kit will be unfinished aluminum so you can finish it any color you want. I'm going to go to PhotoBucket now and get you some pics. stay tuned (or in tune).

__________________

Thanks Guys, Paul E-mail me if you need anything, I don't get around to checking PM's. Pbike257@Gmail.com Last edited by pbike257; 03-11-2014 at 01:11 AM. |

|

#2

|

|||

|

|||

|

__________________

Thanks Guys, Paul E-mail me if you need anything, I don't get around to checking PM's. Pbike257@Gmail.com |

|

#3

|

|||

|

|||

|

glued and screwed lower block

Dry fit right side  Right side from front (ish) angle  Fitting the bottom metal (plastic)

__________________

Thanks Guys, Paul E-mail me if you need anything, I don't get around to checking PM's. Pbike257@Gmail.com |

|

#4

|

|||

|

|||

|

Bottom fit up

Left side complete  Who Built it? What caliber is it?  complete ready to go... anyone got a spare scope?

__________________

Thanks Guys, Paul E-mail me if you need anything, I don't get around to checking PM's. Pbike257@Gmail.com |

|

#5

|

|||

|

|||

|

That's all the pictures of the rifle.... I did have a picture on my phone of the targets... Remember this is Factory ammo I don't load for .243 Winchester.

__________________

Thanks Guys, Paul E-mail me if you need anything, I don't get around to checking PM's. Pbike257@Gmail.com Last edited by pbike257; 03-13-2014 at 05:44 PM. |

|

#6

|

|||

|

|||

|

Very ingenious system!! Looks like it will "lock" things in nicely. Is there a torque setting for all the screws along the sides to get even pressure & alignment? How do you get even pressure on the action from the sleeve? Seems it would take CNC machining to be that precise.

|

|

#7

|

|||

|

|||

|

Quote:

Future blocks will be made on the CNC equipment, This one was the prototype. I will rarely make the first of anything on the CNC.

__________________

Thanks Guys, Paul E-mail me if you need anything, I don't get around to checking PM's. Pbike257@Gmail.com |

|

#8

|

|||

|

|||

|

That's a neat system you came up with. Have to admire a guy who realizes the value of a good dead-blow hammer on the bench! JK

|

|

#9

|

|||

|

|||

|

Very cool, thanks for taking the time to post the pics!

__________________

"I used to wear barrels out fretting over a bunch of things that don't amount to a rats petutie." |

|

#10

|

|||

|

|||

|

Quote:

__________________

Thanks Guys, Paul E-mail me if you need anything, I don't get around to checking PM's. Pbike257@Gmail.com |

|

|

|